3 min read

How to choose the best Managed Print Services

It’s no secret that Managed Print Services have a lot of benefits to offer businesses, particularly in hybrid workplaces. With an integrated,...

Benefit from smart ideas, lower costs, greater productivity. Choose from award-winning printers, software solutions and consumables

Personalised technology solutions to help your organisation gain a competitive advantage

Discover howWe combine professional expertise with a human kind of partnership

Get the right help and advice, register a product and see why our commitment to you matters.

Discover our brand, our global activities and commitments

4 min read

Mark Vella 26/03/2025 12:48:28 PM

Over the past 20 years, global use of materials has increased by more than 65%.1 Electronic waste—a relatively new category—reached 7.3kg for each person on Earth in 2019, for an astonishing total of more than 55m tonnes.2 Research by Deloitte and the Circle Economy Foundation suggests a need to reduce material extraction and consumption by a third,3 among other reasons because these activities are linked to 70% of greenhouse-gas emissions worldwide.4

A favoured answer to these problems is to create a “circular economy”, where at the end of their usable life, products for consumers and industry are put to new uses or turned back into materials for use in manufacturing, beginning the cycle anew.

|

|

“The commitment to sustainability embodies Kyocera’s management philosophy. Through this, we are passing on a company that can continue to grow into the future, and a liveable society to the next generation.” Hironori Ando, president, Kyocera Document Solutions |

Among the companies adopting elements of the circular-economy ethos is Kyocera Document Solutions, which provides MFPs and printers as well as a full range of document-related services.

Kyocera Document Solutions’ parent company, the Japan-based Kyocera Corporation, produces multilayer ceramic chip capacitors (MLCC) used in a wide range of industrial applications, including electronics. The manufacturing process for MLCC involves sheets of polyethylene terephthalate (PET) film. Because the sheets end up with ceramic residue on their surface, recycling the film has been a challenge.

In a new company initiative, this remaining ceramic is removed from the leftover PET film and materials are developed for specific applications using the resulting plastic in parts for Kyocera Document Solutions’ products, such as toner container bottles and internal components.5 An important condition for the use of the recycled PET is that it is tested thoroughly to confirm that its quality and performance are equivalent to newly made material. After repeated tests, the company became the first in the industry to establish technology to upcycle recycled PET materials into components for MFPs and printers.6

|

|

“The concept of sustainability is more familiar and taken for granted by younger generations. There will be a difference between our generation and the younger generation when we become seniors, so I feel that we need to update our way of thinking on a daily basis.” Rina Uenishi, corporate printing parts engineering, Kyocera Document Solutions |

Recycling used PET film for use in further products is part of a long company tradition of caring for nature and using resources efficiently. “Kyocera places importance on coexisting harmoniously with our society, our global community and nature,” explains Hironori Ando, the president of Kyocera Document Solutions. “Based on this ‘living together’ concept, for more than 30 years we have been developing products that extend the life of components for printers and multifunction printers (MFPs), reduce their environmental burden and provide economic benefits to our customers.”

As the environment also becomes increasingly important to customers who use Kyocera’s products, the company will accelerate its efforts to contribute to a sustainable future, says Mr Ando. But even more deeply than that, sustainability is part of Kyocera’s corporate identity and culture.

“The commitment to sustainability embodies Kyocera’s management philosophy,” he explains. “Through this, we are passing on a company that can continue to grow into the future, and a liveable society to the next generation.” Initiatives such as this one for recycling are helping to motivate newcomers to Kyocera’s workforce, while also conserving resources and the environment.

Rina Uenishi works in a parts engineering section of Kyocera Document Solutions’ corporate printing product division, and is responsible for material development and evaluation for this PET recycling project. Her experience shows how the company’s vision for the future helps it recruit talented staff. “When I started working, one of my requirements was whether the company was actively working on environmental issues,” she says. Once at Kyocera Document Solutions, her interests led her to ask to be involved in the recycling initiative. “We hope that it will also attract the interest of our business partners and encourage them to work with us,” she adds.

As younger workers like Ms Uenishi begin to assume management responsibility, Mr Ando’s aspiration is that they will bring a new perspective to their work, balanced with the wisdom of past experience. “We can sustainably change our work in technology development, sales and all other fields,” he says. “I hope that the younger generation of employees will break invisible barriers and change things in a progressive way in the future.”

By attracting determined younger people like Ms Uenishi, Kyocera can develop a new generation of leaders with sustainability-related knowledge and skills. Then it creates an environment where younger employees gain experience in finding sustainable solutions to practical challenges, such as increasing the share of recycled material in the company’s products. In the future, the company plans to expand the use of recycled materials not only for toner containers but also for internal and external parts, aiming to increase the use of recycled materials to 50% per product.

Ms Uenishi observes that education has evolved to make more knowledge about sustainability available during her lifetime. “The concept of sustainability is more familiar and taken for granted by younger generations,” she says. That gives her a reason to keep learning, improving environmental performance and adapting for the future. “There will be a difference between our generation and the younger generation when we become seniors,” she says, “so I feel that we need to update our way of thinking on a daily basis.”

1. United Nations Development Programme, “What is [the] Circular Economy and Why Does it Matter?”, April 24th 2023

2. Conversion from per capita to total uses population figures from United Nations Department of Economic and Social Affairs, “World Population 2019”, accessed October 25th 2024

3. Circularity Gap Reporting Initiative, “The Circularity Gap Report 2023”, accessed October 25th 2024

4. Circularity Gap Reporting Initiative, “The Circularity Gap Report 2021”, accessed October 25th 2024, (This is in the third panel on the “x-ray” graphic, text on the first panel of which begins “So how did we get here?”)

5. Source: brief supplied by Kyocera.

6. Establishment of the industry’s first upcycling technology for multifunction products and printers, October 18th 2024

This article was produced by EI Studios for Kyocera Document Solutions. Find out more.

KYOCERA Document Solutions supports Australian and New Zealand businesses on their digital transformation journey with innovative products and software solutions.

3 min read

It’s no secret that Managed Print Services have a lot of benefits to offer businesses, particularly in hybrid workplaces. With an integrated,...

2 min read

Forward-thinking business leaders are always looking for ways to reduce their environmental footprint, decrease their workplace waste and make more...

4 min read

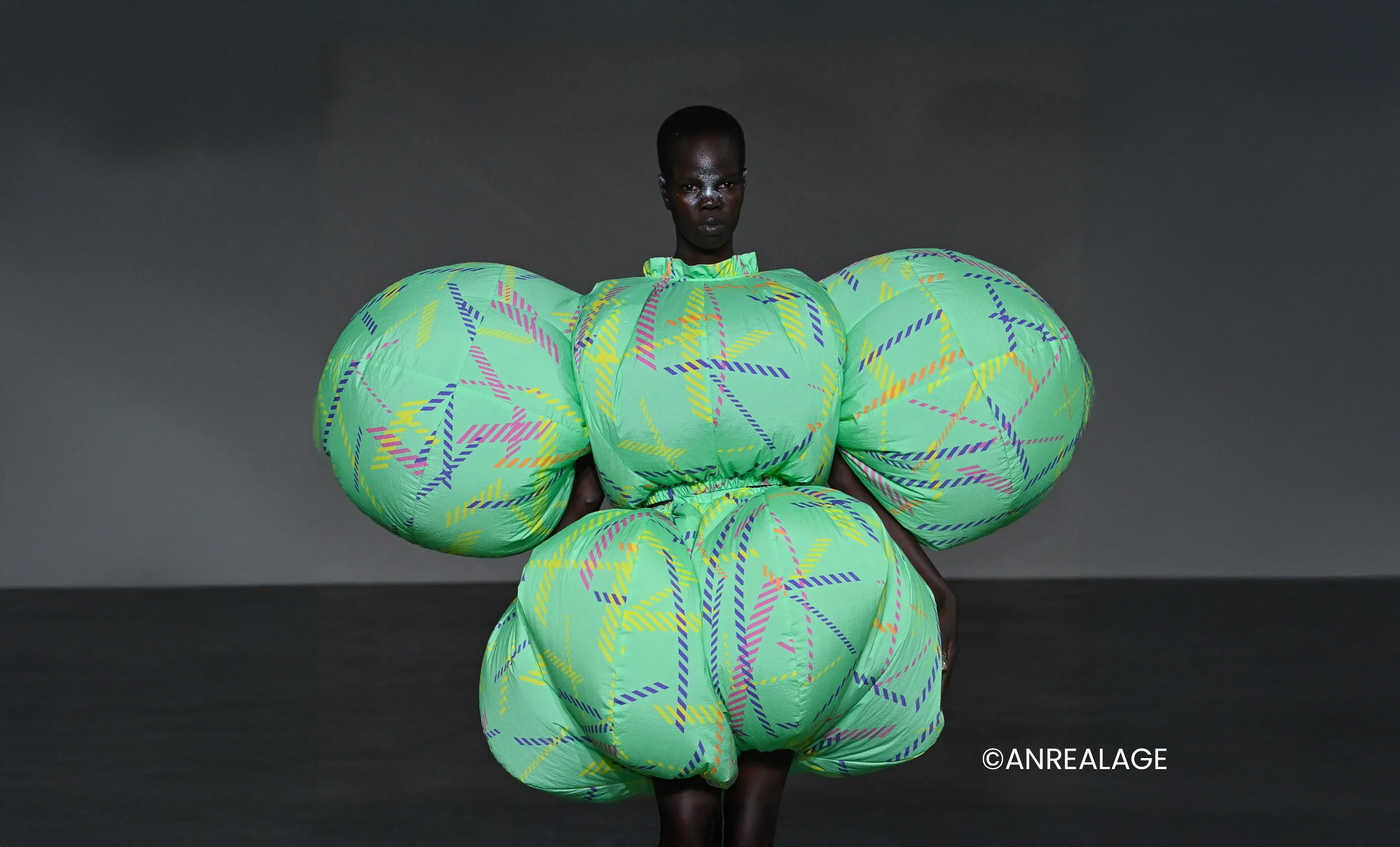

Style aficionados turning to consider the environmental impacts of fashion might first conjure a mental image of mountains of discarded clothing.1 In...